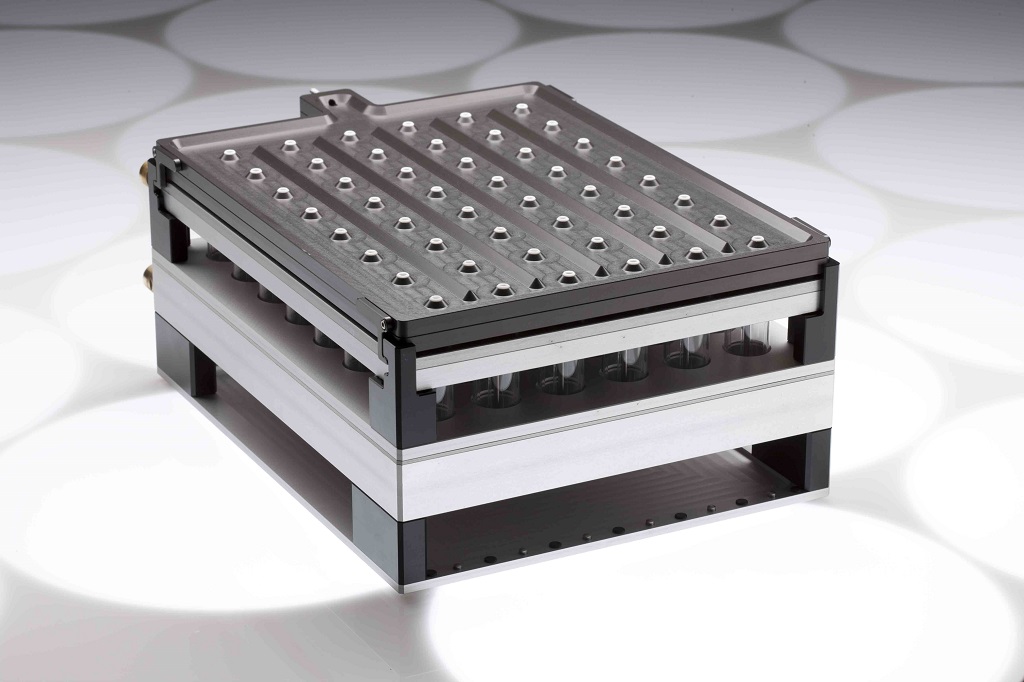

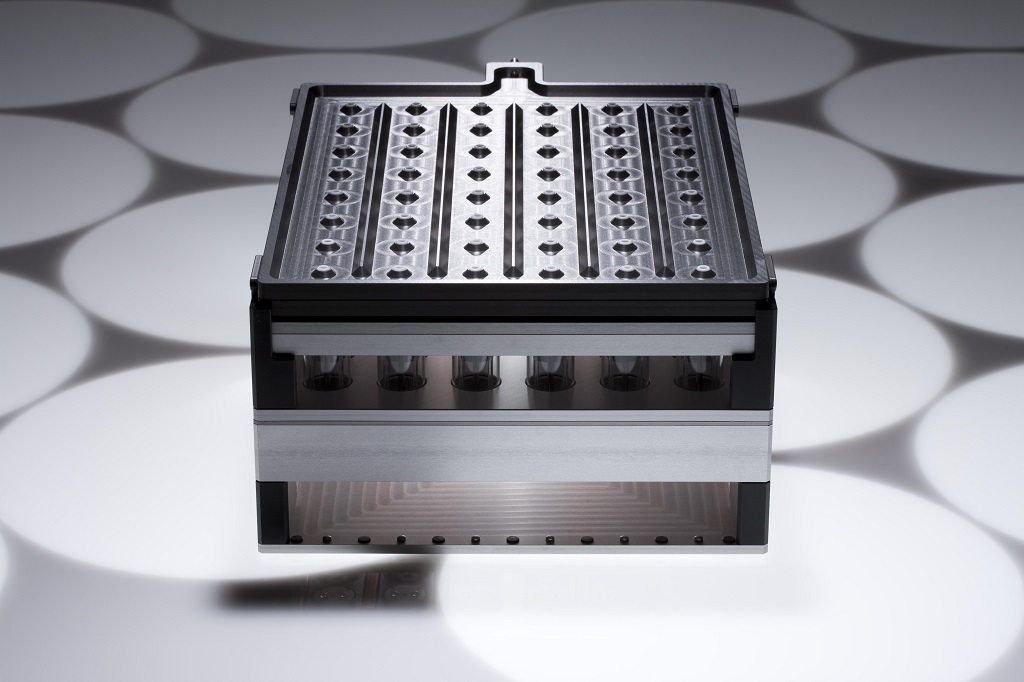

bioREACTOR 48

The 2mag bioREACTOR is an extremely space-saving and user-friendly bioreactor block with 48 parallelized minireactors.

The high degree of parallelization makes it easy to implement high-throughput cultivations in the fields of biotechnology, chemistry and pharmacy. Miniaturisation into the low millilitre scale (8-15 ml) provides a significant saving of material and process costs. This strongly reduces development time and costs for new production processes.

The 2mag bioREACTOR is characterised by an exactly controllable stirring speed with automatic stirrer monitoring as well as precise non-invasive real time measurement of pH and dissolved oxygen (DO). Gassing and mixing of the culture vessels is provided by the gas inducing, inductive stirring elements.

The sterile headspace gassing prevents cross and foreign contamination and enables the cultivation of aerobic and anaerobic microorganisms.

Precisely defined process engineering parameters and the power and oxygen input (kLa > 0.4 s-1), which is comparable to classic stirred tank reactors, ensure simple and reliable scaling of the results.

The bioREACTOR 48 can be integrated into a pipetting robot for fed-batch cultivation, pH control and sampling. We have found an experienced and competent partner in the robot manufacturer Hamilton Bonaduz AG. We will be happy to put you in touch with them.

Parallelization

The bioREACTOR is available in two model variants with 8 or 48 parallel reactors. A still higher parallelisation can be achieved by simoultaneous use of several bioREACTOR units. These can be controlled via an intelligent central software and important process parameters (pH ans DO) can be monitored in real time. In addition, the simoultaneous use of several bioREACTOR units allows the variation of other parameters e.g. the temperature or the stirring speed.

Temperature control

The temperature of the bioreactor block is recorded via an internal Pt100 sensor and can be controlled externally via a thermostat. To avoid evaporation loss, the headspace of the reaction vessels can be cooled down with an reflux cooler. The evaporated water condenses and rests in the reaction vessel. The bioREACTOR with pH and DO sensors can be used at temperatures from 10°C up to 50°C. Temperatures from 0°C up to 65°C are possible without sensors.

Working volume

The working volume of the culture vessels is between 8 and 15 milliliters. This allows repeated sampling without strong reduction of the fermentation volume but also enough capacity for adding pH correction agents or substrates.

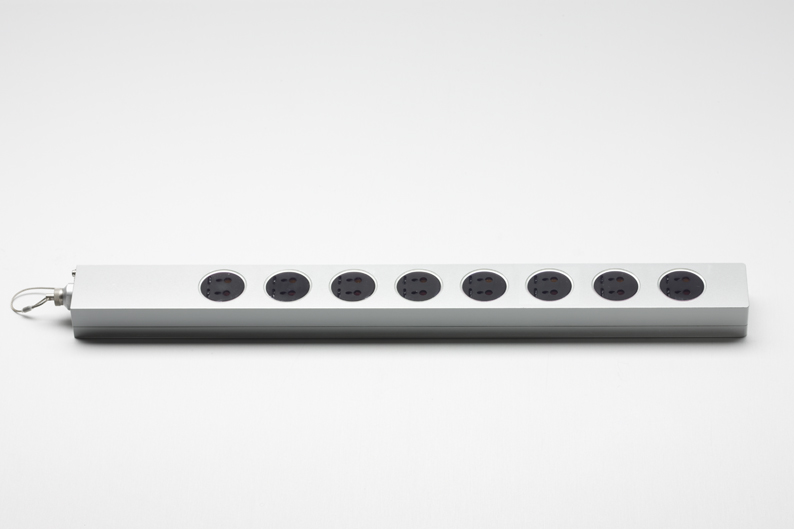

Real-time measurement of pH and DO

pH and dissolved oxygen can be measured in real time during the entire duration of the experiment using a non-invasive optical sensor system. For this, the bottom of the culture vessels are equipped with small sensor spots (pH and O2 sensitive luminescent dyes). The fluorometric measurement is provided by stimulation with light and measurement of the decay time (DLR=Dual Lifetime Referencing Principle, PreSens GmbH). The measuring range lies between 4.0 and 7.5 for the pH and between 0 and 50 % for the dissolved oxygen.

Reaction vessels (disposables)

The disposable culture vessels equipped with sensor points are made of polystyrene and sterile-packed in a set of 2. This allows a time saving and easy equipping of the bioREACTOR. The special geometry of the culture vessels with baffles in combination with the used stirring elements lead to a very good mixing of the medium and to high oxygen transfer rates.

Gas supply

The continuous gas supply of the bioREACTOR can be realized via a gas mixing station. Depending on the used gases (O2, N2, air) aerobic and anaerobic cultivations are possible. The gas transfer into the medium of the culture vessels is done passively through the gas inducing, inductive driven magnetic stirring elements. The gas tranfer rate can be adjusted via the stirring speed.

Stirring bar monitoring

In rare cases, very high cell densities or a high proportion of solids in the medium can cause individual stirring elements to fail. This will be detected in a few seconds and the stirrers will be restarted automatically. Therewith, the stirrer monitoring guarantees a secure experimental run.

Intelligent software

The stand-alone software enables parallel operation of several bioREACTOR 8 and/or bioREACTOR 48 units. At the same time, already finished runs can be compared with new running experiments.

Autoclavability and sterility

All parts that come into contact with the medium are autoclavable or sterile-packed disposable materials. The gassing unit with the fixed stirring elements is completely autoclavable In addition, the complete bioreactor block is sterilisable with ethanol. The disposable culture vessels are sterile packed and were disposed after the experiment. During the experiment, the sterile headspace gassing avoids cross and external contaminations.

Scalability

The precisely defined geometry of the stirring bodies, the precisely characterized process engineering parameters and the power and oxygen input (kLa > 0.4 s-1) through the magnetic stirring bodies, which is comparable to that of conventional stirred tank reactors, enable simple scaling of the results to the liter scale.

Automation

The bioREACTOR can be operated fully automatically by integrating it into a pipetting robot. The integration enables the pH to be controlled, substrate to be added and samples to be taken from the culture vessels. This allows feeding strategies to be investigated, an OD measurement (atline) to be carried out or samples to be taken for further experiments.

For integration, we will be happy to put you in touch with our experienced cooperation partner Hamilton Bonaduz AG. A docking station specially developed for the 2mag bioREACTOR 48 enables the simple and error-free connection of all water-carrying and electrical lines of the bioREACTOR and a simple and robust integration on the robot table.

In addition, a completely new process control software enables the various tasks (sampling, feeding, pH correction,…) to be optimally coordinated and all process data to be stored and visualized.

Technical data

| bioREACTOR | bioREACTOR 48 | |

| Stirring points | 48 | |

| Stirring point distance | 35 mm | |

| Material block | Aluminum, hard-coated | |

| Width | 240 mm | |

| Length (with PreSens sensor bars) | 367 mm | |

| Height | 135.5 mm (without rubber feet); 138.6 mm (with rubber feet) | |

| Weight | 12.0 kg | |

| Electrical data | 230 V / 60 Hz oder 115 V / 50 – 60 Hz | |

| Protection category | IP31 | |

| Culture vessels | ||

| Working volume | 8 – 15 ml | |

| Material | Polystyrene (PS) | |

| Block Temperature | ||

| Permitted operating conditions (with sensors) | +10 °C up to +50 °C (at 60% humidity) | |

| Permitted operating conditions (without sensors) | 0 °C up to +65 °C (at 60% humidity) | |

| Mixing | ||

| Stirring element | gas inducing stirring elements | |

| Stirring speed | 100 – 4,000 rpm | |

| Gassing | ||

| Flow rate | 4.8 l/min | |

| Real-time measurement | ||

| pH range | 4.0 up to 7.5 | |

| DO range | 0 – 50 % O2 | |

| Order no. | 100730 | |

1 year warranty on material and manufacturing defects.

Subject to technical changes. We do not assume liability for errors in printing or typeing.

Comparison

| bioREACTOR | bioREACTOR 48 | bioREACTOR 8 |

| Stirring points | 48 | 8 |

| Stirring point distance | 35 mm | |

| Block material | Aluminum, hard-coated | |

| Width | 240 mm | 65 mm |

| Length (with PreSens measuring bars) | 367 mm | |

| Height | 135.5 mm (without rubber feet); 138.6 mm (with rubber feet) | |

| Product weight | 12.0 kg | 3.1 kg |

| Connected load | 230 V / 60 Hz or 115 V / 50 – 60 Hz | |

| Protection class | IP31 | |

| Culture vessels | ||

| Working volume | 8 – 15 ml | |

| Material | Polystyrene (PS) | |

| Block Temperature | ||

| Permitted operating conditions (with sensors) | +10 °C up to +50 °C (at 60% humidity) | |

| Permitted operating conditions (without sensors) | 0 °C up to +65 °C (at 60% humidity) | |

| Mixing | ||

| stirrer | Gas-inducing magnetic stirrer | |

| Speed range | 100 – 4,000 rpm | |

| Gassing | ||

| Flow rate | 4.8 l/min | 0.8 l/min |

| Real-time measurement | ||

| pH range | 4.0 to 7.5 | |

| DO range | 0 – 50 % O2 | |

| Order no. | 100730 | 101530 |

1 year warranty on material and manufacturing defects. Subject to technical changes. We do not assume liability for errors in printing or typeing.

Applications

Aerobic and anaerobic cultivation of bacteria, yeasts and funghi

Aerobic and anaerobic cultivation of bacteria, yeasts and funghi Evaluation of adequate production strains (strain development)

Evaluation of adequate production strains (strain development) Media screening and optimization

Media screening and optimization Optimization of the process design (manual batch or automated batch or fed-batch process design with pipetting robots)

Optimization of the process design (manual batch or automated batch or fed-batch process design with pipetting robots) Cell growth experiments

Cell growth experiments Studies of gene and protein expression

Studies of gene and protein expression Viabily tests

Viabily tests Inhibition and toxicity experiments

Inhibition and toxicity experiments Enzyme assays

Enzyme assays Quality control

Quality control Also applicable for chemical and enzymatic reactions

Also applicable for chemical and enzymatic reactions